A Metal Core PCB (MCPCB), also known as Metal Core Printed Circuit Board, is a type of PCB where the base material is made of a metal, typically aluminum or copper, instead of the traditional fiberglass. MCPCBs are primarily used for applications that require superior heat dissipation, as the metal base allows for better thermal conductivity compared to standard FR4 PCBs (fiber-reinforced epoxy laminate).

Key Features:

- Metal Substrate: The primary feature of an MCPCB is the metal core, which serves as the base The metal core is typically aluminum, copper, or other metals known for their high thermal conductivity properties.

- Superior Heat Dissipation: The metal core helps dissipate heat more effectively, preventing overheating of sensitive components and improving the overall performance and longevity of electronic devices.

- Thermal Management: MCPCBs are designed to withstand high temperatures and to manage the heat generated by components, making them ideal for high-power applications.

- Layer Structure: MCPCBs typically have three layers: a metal base (core), an insulating layer, and a copper circuit The metal core serves as the heat sink, while the insulating layer electrically isolates the metal base from the copper layer.

Applications:

- LED Lighting: One of the most common applications of MCPCBs is in LED lighting, particularly in high-power LED modules where heat management is critical to avoid degradation and failure of the light source.

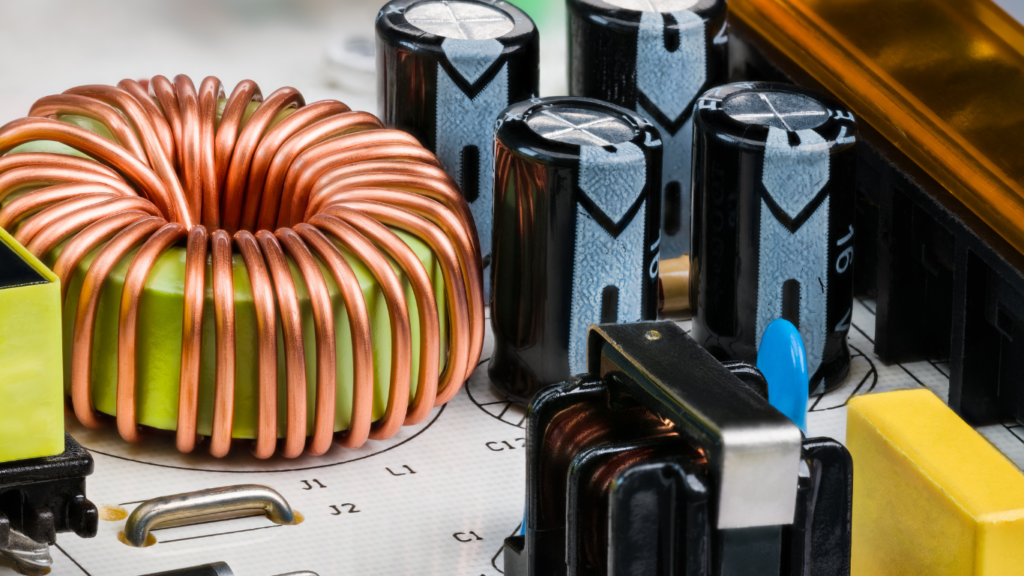

- Power Electronics: MCPCBs are widely used in power electronics, such as inverters, converters, and power supplies, where high currents and heat dissipation are essential for optimal performance.

- Automotive Electronics: In automotive systems, MCPCBs are used in areas like lighting, sensors, and power modules, where heat dissipation and reliability are critical.

- Telecommunication Equipment: MCPCBs are used in high-power telecommunications systems, including base stations, RF amplifiers, and signal processing equipment, where efficient thermal management is necessary.

- Industrial Electronics: MCPCBs are used in machinery and industrial control systems that involve high power components requiring effective heat dissipation.

Advantages:

- Excellent Heat Management: MCPCBs effectively conduct heat away from sensitive components, preventing overheating and improving system reliability, particularly in high- power

- Improved Durability: The metal core improves the board’s mechanical strength and durability, which is beneficial in rugged applications like automotive and industrial

- Compact Design: MCPCBs allow for compact designs, as heat management is handled more efficiently, enabling the use of smaller components in high-power applications.

- Enhanced Performance: By effectively managing heat, MCPCBs help ensure consistent performance over time, reducing the risk of component failure due to thermal

Metal Core PCBs (MCPCBs) are essential for applications where effective heat management is crucial. They offer excellent thermal conductivity, enhanced performance, and reliability, making them perfect for high-power electronic devices, LEDs, automotive systems, telecommunications, and industrial electronics. While they are more expensive and complex to produce than traditional FR4 PCBs, the benefits in heat dissipation, durability, and performance make them invaluable in many industries.