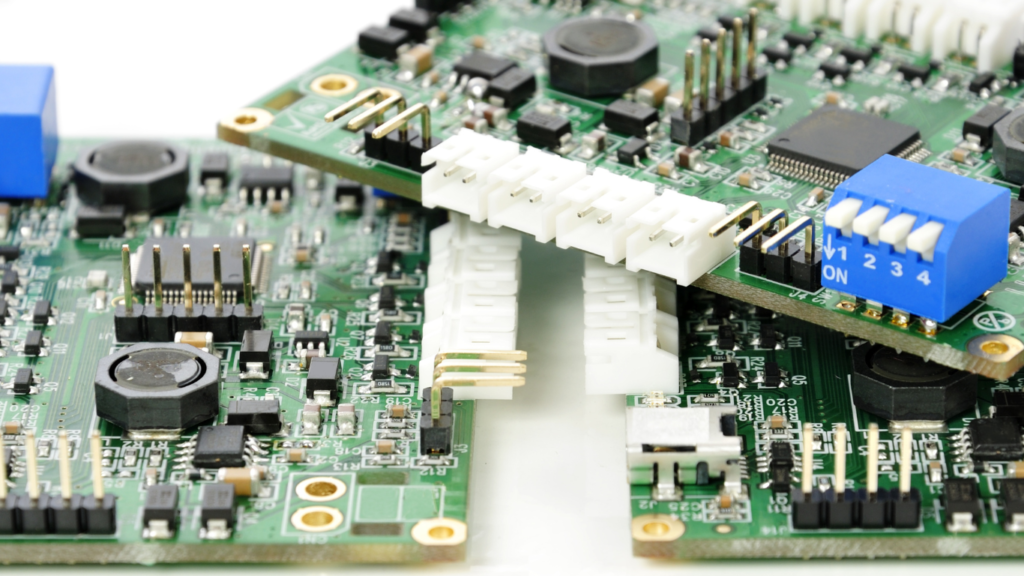

PCB Assembly Services involve the process of assembling and soldering components onto a printed circuit board (PCB) to create a fully functional electronic device. Our PCB assembly services are designed to provide high-quality, reliable, and efficient assembly of both through-hole and surface-mount components for a wide variety of industries. We offer end- to-end solutions from component sourcing and PCB design to final assembly and testing.

Key Services We Offer:

1. Surface Mount Technology (SMT) Assembly

- SMT is a popular method for assembling electronic components directly onto the surface of the Our SMT assembly services offer high-speed, accurate placement of components, even for complex, fine-pitch devices. We use advanced pick-and- place machines for precision placement and automated soldering processes such as reflow soldering.

2. Through-Hole Technology (THT) Assembly

- For larger components or those requiring extra mechanical strength, through-hole technology is Components are inserted through holes in the PCB and soldered on the opposite side. Our experienced team handles both manual and automated through-hole assembly processes, ensuring reliable solder joints and secure component connections.

3. Mixed Technology Assembly

- Many PCBs require both SMT and THT assembly processes. We offer mixed technology assembly services, integrating both surface-mount and through-hole components onto a single Our team ensures that each component is placed

with precision, and the assembly process is carefully managed to meet all design requirements.

4. Component Sourcing and Procurement

- We help source high-quality components for your PCB assembly, ensuring that all parts meet industry Whether you need common or hard-to-find components, we leverage our extensive supplier network to ensure you get the right components at the best price.

5. Prototype PCB Assembly

- If you’re in the early stages of product development or need a small batch for testing, we provide prototype PCB assembly We work closely with you to ensure that your design works as intended before moving to mass production, providing quick turnarounds for prototypes.

6. Volume PCB Assembly

- We cater to both low-volume and high-volume PCB assembly Whether you need a few boards or large-scale production, we have the capacity to scale up quickly and efficiently. Our automated assembly processes ensure that each PCB is assembled with precision and meets the required quality standards.

7. PCB Testing and Inspection

- We provide comprehensive testing and inspection services to ensure that your PCB performs as intended. This includes functional testing, automated optical inspection (AOI), X-ray inspection for hidden solder joints, and electrical testing to verify that the connections are We also conduct in-circuit testing (ICT) for more thorough quality assurance.

8. Rework and Repair Services

- In case any issues arise during the assembly process or if you need modifications to a pre-assembled PCB, we offer rework and repair services. Our team can fix soldering defects, replace faulty components, and perform any necessary adjustments to get your board working as expected.

9. Box Build and Final Assembly

- For more complex projects, we offer box build services, which include assembling the final product by integrating the PCB into its enclosure along with other necessary components like wires, connectors, and displays. This service is ideal for projects that require the final product to be ready for delivery or use.

10. Packaging and Shipping

- Once the assembly is complete, we ensure that the PCBs are carefully packaged to prevent any damage during We offer reliable shipping services to get your products to you safely and on time, whether it’s a small batch or a bulk order.

Advantages of Our PCB Assembly Service:

- High-Quality Assembly: We focus on precision and quality, ensuring that each PCB assembly meets industry standards and functions reliably in its application.

- Fast Turnaround: With a streamlined assembly process and advanced machinery, we offer quick lead times for both prototypes and mass production.

- Customization: We provide flexible services tailored to your specific requirements, whether it’s for a unique design, a specialized component, or custom packaging.

- Cost-Effective Solutions: We help reduce overall production costs by offering competitive pricing, efficient assembly processes, and sourcing quality components at the best

- Experienced Team: Our team of engineers and assembly experts ensures that your PCBs are assembled accurately, with attention to detail in every step of the process.

Our PCB Assembly Services offer a comprehensive, efficient, and reliable solution for bringing your electronic products to life. Whether you’re working on a prototype or need high-volume production, we have the expertise, tools, and resources to deliver high-quality PCBs that meet your performance, cost, and timeline requirements. Contact us today to discuss your project and get a tailored PCB assembly solution that meets your needs.