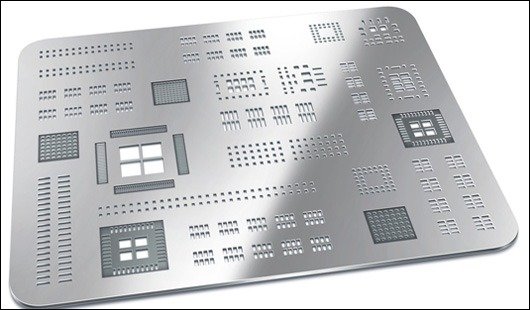

PCB Stencil Service is a crucial part of the PCB assembly process. It involves creating precise metal stencils used for applying solder paste onto a PCB’s pads. These stencils ensure that the correct amount of solder paste is deposited in the right places, which is essential for creating reliable, high-quality solder joints during the component placement process.

Our PCB stencil service offers the design, fabrication, and delivery of stencils tailored to your specific PCB assembly requirements, ensuring precision and efficiency in the soldering process.

Key Services We Offer:

1. Custom PCB Stencil Design

- We provide custom stencil designs based on your PCB layout, ensuring that solder paste is accurately applied to the pads and vias. We consider the type of components (such as fine-pitch components) and optimize the stencil design to match your board’s needs.

2. Laser-Cut Stainless Steel Stencils

- Our stencils are made from high-quality stainless steel using precision laser cutting technology. This process ensures that the stencil has clean, accurate apertures for precise paste application. Stainless steel offers durability and consistent performance over many PCB assembly cycles.

3. Hydraulic Stencils

- For applications requiring thicker solder paste deposits or specific designs, we also offer hydraulic stencils. These are ideal for fine-pitch components and help improve paste release.

4. Fine-Pitch and Micro-Pitch Stencils

- For designs that involve fine-pitch or micro-pitch components, we create highly detailed and precise stencils to accommodate the tight pad spacing, ensuring accurate solder paste application and preventing bridging.

5. Step Stencils

- Step stencils are used for multi-layer PCBs where different solder paste thicknesses are required for various areas of the We provide step stencils to ensure optimal paste deposition in areas that require thicker or thinner layers of paste.

6. Stencil for Through-Hole Components

- We can design stencils specifically for through-hole components, ensuring that the paste is applied correctly to the through-hole pads, optimizing the soldering process and reducing the risk of defects.

7. Stencil Cleaning and Maintenance

- We also provide stencil cleaning and maintenance services to ensure your stencils remain in good condition for long-term use, maintaining their accuracy and performance in each soldering cycle.

8. Quick Turnaround

- We understand the importance of meeting deadlines, so we offer rapid fabrication services, delivering high-quality stencils with fast turnaround times to ensure your PCB assembly processes stay on schedule.

9. Prototyping and Low-Volume Stencils

- Whether you’re working on a prototype or a small production run, we can design and fabricate stencils tailored to low-volume needs, ensuring cost-effectiveness without sacrificing quality.

Advantages of Our PCB Stencil Service:

- Precision and Accuracy: Our stencils are designed to ensure that the right amount of solder paste is applied in the exact location, reducing the risk of defects and improving solder joint

- Optimized for Your Design: We tailor each stencil to the unique requirements of your PCB design, whether you have fine-pitch components, high-density circuits, or through-hole

- Enhanced Efficiency: Accurate paste application leads to fewer rework cycles, faster production, and more consistent assembly results.

- Cost-Effective for Prototypes: For prototype runs or low-volume production, we provide high-quality stencils at affordable prices, ensuring your prototype assembly process is smooth and efficient.

- Durability and Long Life: Our high-quality stainless steel stencils are built to last, withstanding multiple reflows and maintaining their precision over time.

Our PCB Stencil Service ensures that your PCB assembly process is smooth, efficient, and of the highest quality. With our custom-designed, precision-engineered stencils, you can expect accurate solder paste application that leads to improved solder joints, faster production, and reduced defects. Whether for prototyping, low-volume production, or high-volume runs, our service is tailored to meet your needs. Contact us today to learn more or to request a quote for your PCB stencil requirements!